Aviation

London Calling

The solid strategic partnership between the UK, Italy and Japan meets at DSEI in London to show progress on GCAP, the next-generation system to protect the skies in the coming decades.

Sep 2023

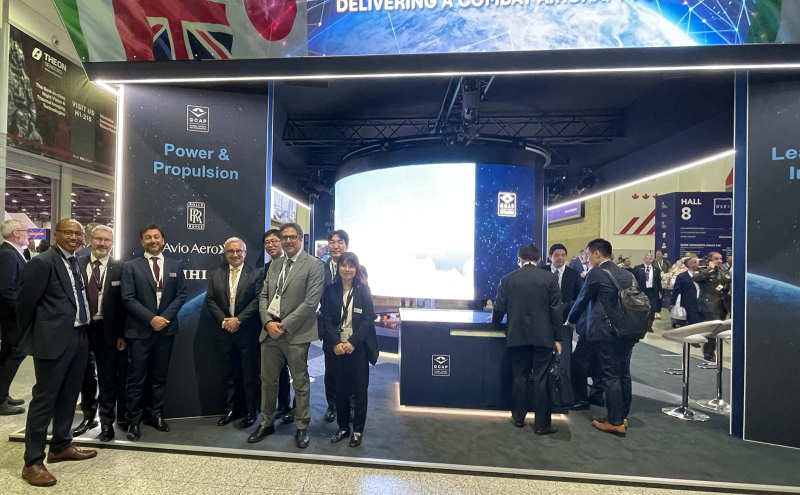

Thousands of professionals, operators, military and government delegations who, from September 12 to 15, converged on London's Excel - the exhibition area located between London City Airport and the Canary Warf financial center - were very likely (or with certainty, if entering from the west gate) to have stared at the next generation fighter jet, the Global Combat Air Program, presented through an impactful "phygital" exhibit display.

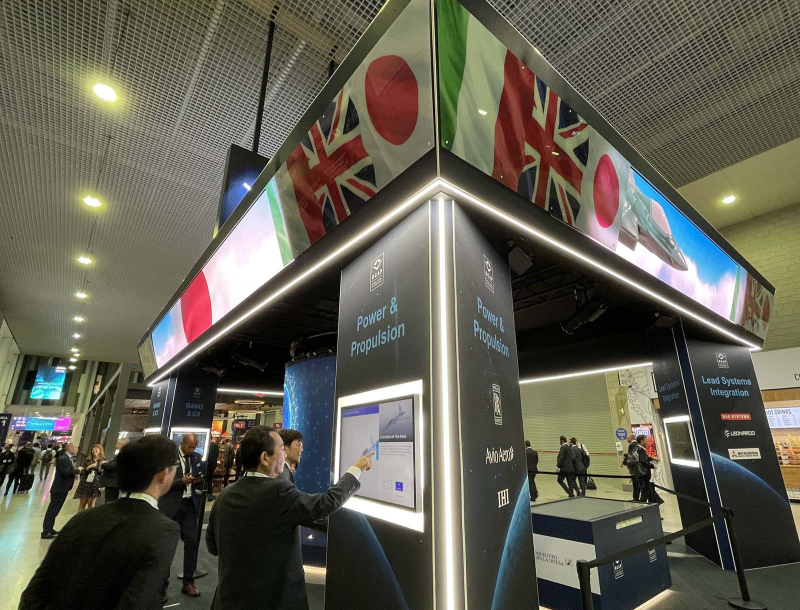

At Defence & Security Equipment International (DSEI) this year, GCAP’s stand stood out among the more than 1,500 exhibitors, including various industries and enterprises of all sizes in the defense sector. The stand was a kind of post-modern temple, an emblem of high technology and innovation. A giant screen, in turn, topped the upper frame made of LED monitors. The supporting pillars represented the four technological domains with interactive screens and domain experts available to guide visitors through: system integration, weapons, digital-AI, and power and propulsion solutions.

The GCAP was launched in December 2022 by the governments of the United Kingdom, Italy and Japan to develop and build a sixth-generation system of systems. The program features national industrial strategic partners for each domain of expertise, and the integration of the whole system is led by BAE Systems, Leonardo, and Mitsubishi Heavy Industries. The Power & Propulsion domain management sees Rolls Royce, Avio Aero, and IHI Corporation teaming up to develop and implement the next generation of engines.

On the very first day of DSEI, the three national companies leading the program announced the start-up of activities to define the terms of the trilateral collaboration to meet the requirements of the conceptual phase of the system (e.g., long-term working arrangements and capability).

In addition to this - as part of the program packed with workshops, presentations, and conferences on the agenda at DSEI in London this year - leaders from the three companies, along with international directors from the three governments, held a panel discussion to provide updates on progress toward the entry into service of the new-generation fighter jet scheduled by 2035. The program will have a generational impact, as it already involves more than 9,000 people in partner companies, in addition to the approximately 1,000 suppliers directly involved in the supply chain.

From the morning of the first day and throughout the next four days, the joint team of Avio Aero, Rolls Royce, and IHI illustrated through videos and 3D touchscreen projections the capabilities and key features of the two engines that will take the futuristic fighter jet into the air at up to supersonic speeds. It will be the first one with a gas turbine integrated with an electric system capable of generating a higher level of power at takeoff and beyond.

The high capacity to generate electrical power will (just pushing a button, where necessary) guarantees greater power storage. At the same time, this will provide a way to reduce the overall mass and weight of the engine, while simplifying its architecture. To ensure the proper operation of all engine components and guarantee the total efficiency of the aircraft, one of the basic requirements is precisely the ability to generate significantly more electrical power than the current generation of aircraft.

Also, to reduce weight and operating costs while improving performance, the three companies will use new-generation composite materials and metal alloys that are lighter and more resistant to high temperatures to build the engine. On this subject, additive manufacturing technology will be instrumental, as will using the latest digital design tools.

Many innovations and technological applications piqued the interest of those who approached the Power & Propulsion domain leaders, such as Massimo Castorina - Avio Aero's Marketing and Business Development Leader. "It was important to give visibility and present our solutions on a stage like DSEI to the ‘professionals'. And it was an opportunity to meet the future users of the three national and industrial partners with whom we are now working at full capacity to develop this strategic and fundamental project for the future of our companies".

On the other hand, the UK colleagues emphasized "the opportunity to present progress and solutions to the group of partners and also to potential customers (pilots, air forces, governments), which can provide insights from end users and ultimately strengthen the chances of moving forward expeditiously with work deliveries," said Mark Tivey, Business Development Director of future programs for Rolls-Royce.

One of the innovations that Rolls Royce will bring to the trilateral table of the Power & Propulsion collaboration is the patented Distortion Tolerant Fan System. Thanks to the aircraft's sophisticated air vents, this advanced fan can take full advantage of airflow and thus provide efficient and stable performance. As well as control and manage the flow to adapt the engines to each type of system/aircraft operational mission.

The last time the GCAP partners met together at an industry event was just a few months ago, last March, at the DSEI edition in Tokyo, Japan. Going through the London experience, the IHI team recognized its global scale and even came across a far larger audience. "It was a great opportunity," commented Koji Kodama, F-X Engine Development Department Manager at IHI. "It had been since DSEI in Tokyo that we had not met so many stakeholders from partner countries, and it was interesting to interact with all of them. These opportunities are advantageous in continuing our cooperation."