Humans

A Golden Anniversary

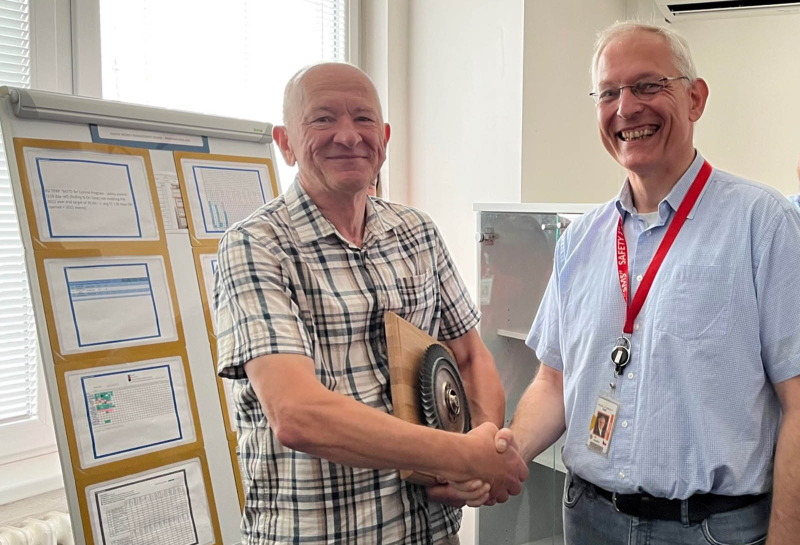

The inspiring conversation with Jiri Vitek from Prague, who celebrates his remarkable 50 years of designing and building engines with much love and experience to share among his lucky colleagues.

Aug 2023

Last month at the Avio Aero Prague site, home of the GE Turboprop engines, a special event celebrated this incredible milestone of an engineer’s 50th work anniversary. Jiri Vitek has a truly interesting story to tell — besides this impressive achievement.

At the age of 15, a young boy from a small Bohemian village comes to Prague for an apprenticeship: growing curious and ambitious too, he completes his high school education and then continues his studies at the Czech Technical University of Prague to become an experienced and skillful engineer as well as an adept at the aviation industry.

He is an inspirational person for his junior and senior colleagues, as well as a role model for the young generation of engineers; a respected mentor who leads by example. All traits that we got confirmed during a special conversation with this precious personality.

Would you tell us about your education and professional youth? How old were you when you started at Walter Engines?

“After completing primary school in 1970, I wanted to go to university. The condition at that time was that I had to choose a manual working profession first. Therefore, at the beginning I was trained to be a turner at the national company Motorlet (Walter), signed a contract of employment, worked at the factory and continued my secondary school education at the same time. Then, I started studying at the Czech Technical University in Prague. I went to university as an employee with the condition that I would return to Motorlet when I graduated from my field of study, which was focused on aircraft engines”.

When did you celebrate your 50th anniversary and what does it mean to you?

“I signed my first employment contract on July 1, 1973. I don't really enjoy anniversaries (they are just a reminder of how old you are!) but it's a huge piece of my life and, in this case, my entire professional life. I guess it’s not so common to stay in one workplace for so long these days. Looking back at the last 50 years: I’ve spent that time doing the job that I chose myself and that I enjoyed doing which brought me not only financial security, but it allowed me to gain a lot of professional knowledge, experience and even joy. In addition, my work has allowed me to meet a very long list of co-workers that I respect as both people and colleagues. I have a lot of fond memories associated with them."

What were the main benefits and the most difficult challenges of working and studying at the same time?

“The period when I worked in production and studied at the same time was during my high school. I think the hardest thing was staying motivated to get my high school diploma: at the age of 18, going to work in the morning and to school in the evening is not your dream life. Once at university, I no longer had to work in production every day. I only went to help occasionally, to earn some extra money for my studies. This practical experience in production was an ultimate asset for my whole career: I’ve learnt that my design requirements for engine parts must align with real production possibilities. Even the best design idea is meaningless if it is not feasible”.

What were your professional ambitions or interests in your youth?

“My interest in aircraft engines started while I was working in production. I became interested in what the part I was machining would be used for. I had a senior friend in Engineering who used to explain to me the design and function of each part. I was so intrigued and wanted to become someone who could not only make the parts but also design them. And that was the real beginning and the reason for me to study aviation engines at the university”.

"Aviation has a unique and amazing dimension for me and that is the flight itself, this is an excellent motivations but also a challenge when it comes to the design and construction of an aircraft engine"

How many positions have you been through in your career, and which ones have you been most interested in and excited about?

“Leaving aside my experience as a turner, after graduating from university in 1980, I joined the Turbine Design Group development department. At that time, the M601 engine was the main focus of my work. I was mainly involved in preparing and evaluating tests and implementing design improvements to increase engine reliability and durability. The development of the M602 engine had started right then, and I was in it as well. I had the opportunity of working on new projects. In addition, I was lucky to work with a great team of knowledgeable colleagues, willing to share their knowledge and experience. During the period of political changes in the Czech Republic after 1989, the organizational structure and ownership of the company changed. There was a general decline in development work, including the termination of the M602 program and changes in the customer market. During this time, I worked in various management positions, mainly focusing on projects for a growing number of different engine builds. At Walter Engines, I was leading the Design department. Then GE came with a new perspective of evolving the development of the M601 with the new H Series engine. My primary role was to manage the work associated with the design changes and subsequent certification. Today, I work in the Systems Team as a Principal Engineer and Compliance Verification Engineer. I see my main role in helping my younger colleagues, sharing my experience with them, and to motivate them so they can do their job with passion”.

You have worked with the turboprop engines for many decades. How do you feel this specific industry segment changed overtime?

“If you think about the engines we handle here, it is not easy to compare the state of the art at the beginning of M601 development with the Catalyst today; with regards to technologies and design tools, production capabilities, or market demand. The M601 engine was a one-turbine turboprop engine designed and built by a relatively small team at Motorlet. Its development began in the 1960s and was designed for the small L410 commercial aircraft. Over time, its basic design has not changed significantly. Still, the requirements for increasing performance, durability and the number of design changes for various airframes have grown, and it has been – as it still is – a very complex activity. The Catalyst engine is much younger. It uses cutting-edge design and technology methods and tools in its design, supported by a broad international team of experts. State-of-the-art tools and technologies are used for production, including 3D printing, with top-of-the-range parts and engine testing equipment. I'm a little envious of my Catalyst teammates. I firmly believe in this engine, both technically and in the fact that it will find its place in today's market. I believe it will bring joy and benefit to my team and company, as well as a lot of new knowledge and experience”.

"I believe that the new Catalyst engine will bring joy and benefit to my team and company, as well as a lot of new knowledge and experience"

What would you recommend to a young engineer or aerospace professional who would like to join this industry, perhaps the Prague site?

“Every industry has its strengths and pitfalls. Personally, aviation has a unique and amazing dimension for me and that is the flight itself. This is excellent motivation but also a challenge when it comes to the design and construction of an aircraft engine. Every idea that brings more power, less consumption, less weight, and greater durability is worth more than gold. But never at the expense of safety and reliability, which is always the top priority. Developing an aircraft engine involves the teamwork of experts from many professions and nationalities. Working on an engine like Catalyst, we don't divide teams into Czech, Italian, German or Polish people. We are one team working towards a common goal. Since I am in daily working contact with them, I can describe the Prague team as a group of people who are motivated and fully aware of their priorities”.

What do you like to do in your free time?

“I live in Prague with my partner. I don't like boring life, so I try to divide my time between work, my family (especially my four grandchildren), working on my cottage and finding time to travel and see new things. It doesn't matter if it’s the north of Norway or southern Bohemia. I like getting to know new places and especially meeting new people. My physical activities are not exactly what you’d call "sport" but I like walking or riding a bike”.

What are your most significant motivating factors, and have they changed during your long career?

“As mentioned, my first motivation was my interest in studying and learning the skills needed to build an engine. Over time, I realized it is a never-ending, continuous process of learning and gaining experience. Also, with a product as complex as an aircraft engine, I’ve come to realize just how important teamwork is. This became my key motivation, especially when I was leading the Design Department team: to coordinate my team’s work while cooperating with other departments, and not only on the professional level. I’ve always considered the motivation to achieve a common goal my main priority, and I was lucky to have team members who were on the same page. Even today, I try to promote these motivation factors in my daily work with younger colleagues”.