Humans

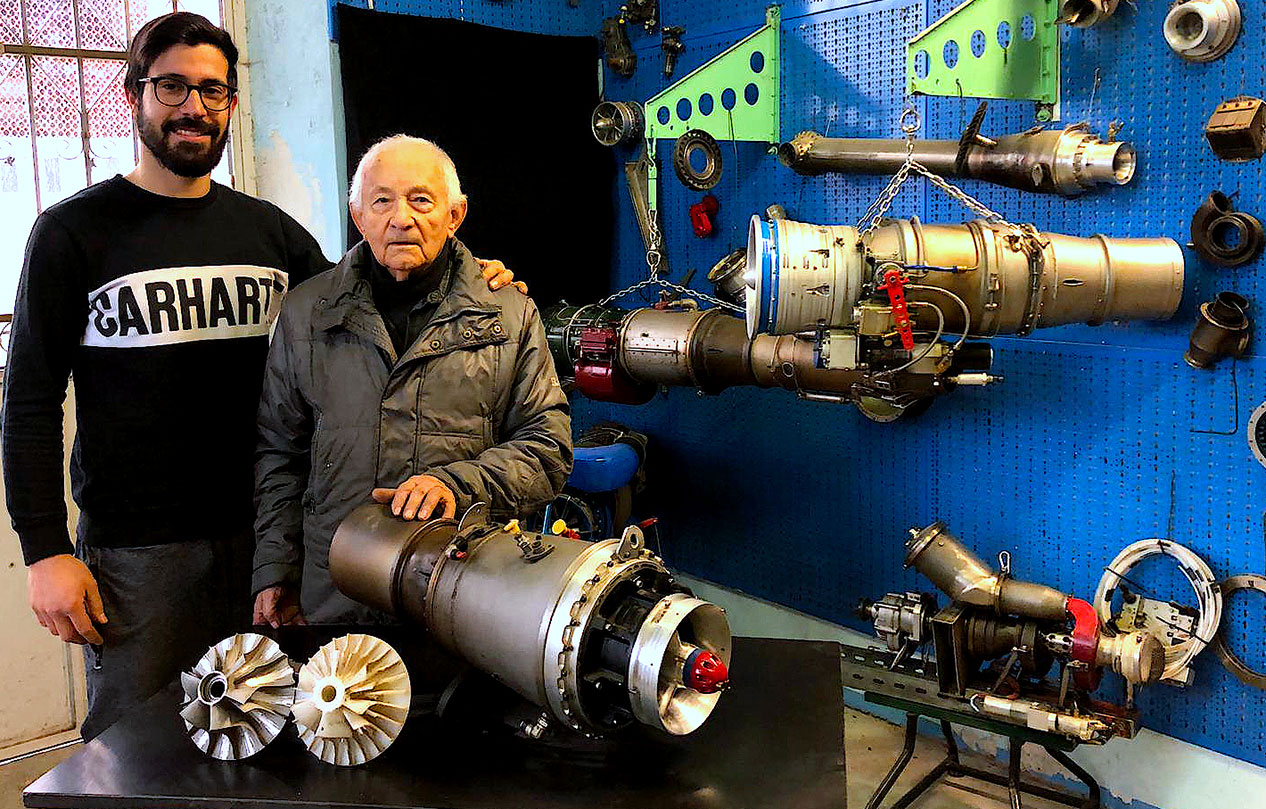

Thank you, Grandpa!

A specialist in aircraft engine testing and his "genetic" attraction to turbines, precision mechanics, and scale reproduction of objects that can be fired up, for real.

Dec 2018

Alessandro Loiercio was born in 1991 and works as a Test Operator at the Experimental Centre at Avio Aero Sangone. He joined the company in 2011 after graduating as a mechanical technician from the Avogadro Technical Institute in Turin. Alessandro then completed a specialization course in mechanical processing that prepared him for his work in the experimental test center of Turin. Here, Alessandro prepares systems and test rooms, where then he subjects Avio Aero products (such as transmissions or turbines) and whole engines to basic testing to certify their use in flight.

Alessandro is a die-hard of aeronautics fan, and that is why he chose a technical field, but what makes a remarkable difference in his story is his grandfather’s influence. In fact, despite being first an automotive professional and then a coffee machine manufacturer, his grandfather, Virginio, has always been a self-taught designer and craftsman of miniature aeronautical turbines. "They are all different types," Alessandro says. "My grandpa has always reproduced miniature turbines with three axial and one centrifugal stages, or just centrifugal or just axial stages.”

Alessandro grew up watching and appreciating as his grandfather built these tiny mechanical masterpieces, and he has tried his hand at making them: “The latest creation is a full, 25 cm diameter turbofan engine,” says Alessandro. Nevertheless, the amazing detail of these miniscule objects is that they really work, with real fuel. Just think: the last turbofan, built by grandfather Virginio, even has its own small combustion chamber!

So, we can say that your passion is written in your DNA?

"That's right. I inherited it at a very young age. With my grandfather, I started building my first turbines and doing my very first engine tests at the age of 8 in the garage of his country house. For these occasions, it was transformed into a test room. We still make real small-scale aeronautical turbines starting from automotive components and waste materials. Curiosity and inventiveness are definitely a family trait."

And then you ended up working in one of the most important aeronautical companies...?

"Here at the Sangone Experimental Centre I immediately became part of a group that is like a big family. My colleagues put me on the test bench and taught me a lot. I began working as a test operator and the first engine I saw running on our test benches was the TP400, which powers the enormous Airbus A400M. I was immediately fascinated to see a test bench assembled and to be able to run engine tests on a product that is already in service, that flies regularly. It's a complex job, which requires knowledge of the whole engine system: from the gearbox to the hydraulic connections, and even the electrical system.”

In your work, you also follow the tests of complete engines and brand new models, such as the GE Catalyst, right?

"I can say that I saw the birth of this turboprop. I literally followed its development: I was in Prague at GE Aviation Czech for six months for the entire testing phase and I was there during FETT (First Engine To Test) last December. Later I followed the engine to Canada for the altitude test. I will always remember the great excitement of seeing the first ignition of a new engine... as well as the incredible responsibility of having to test an engine in record time and to have a good product at the first try!”

What do you like best about your work?

“I could never be bored with my everyday life. Each test is different from the previous one: you need to have a flexible mind and creativity to find innovative solutions.

I also love field missions: assessing the condition of an engine and working on it, working right under the wing of an airplane. That is one of my favorite things about my work trips. Not to mention that the possibility of travelling, even for quite long periods, has taught me a lot about relationships with colleagues, comparing other cultures, other working methods and viewpoints provides great personal and professional enrichment.”

If you had to give a young colleague some advice, what would you say?

"I would tell him to continue studying and to never stop seeking knowledge: preparation is essential. But if you are lucky enough to find - as I did - a job that fascinates you, you should grab the opportunity! In the future I hope to be able to continue to provide technical assistance in the field: following the engine on the aircraft is my absolute favorite thing to do, although, perhaps one day, I might open my own business.”

You certainly have a fascinating and equally challenging hobby: the restoration of vintage cars...

"That's right, a hobby that I've neglected a little due to many commitments and business trips lately, unfortunately. Over the years, I have restored a 1968 Mustang, as well as an unknown number of Vespas and a Guzzi Falcone 500. Now my goal is to renovate the house I just bought!"